PRODUCTS

- Home

- PRODUCTS

DESIGNING PRODUCTS FOR A NEW ERA

Power Kits offers a wide range of industrial products and solutions of a superior quality and technical specifications. All our products conform to the applicable IS Norms in accordance with customer designs. We only use materials of the highest quality to ensure that our customers always get the best.

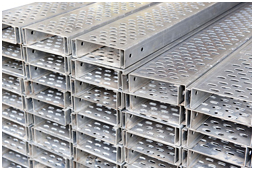

Perforated Cable tray

Designed for robustness in long-span applications, Perforated Cable trays act as a bridge that allows for safe transport of wires and cables across open spans. It can be regarded as the structural component of a building's electrical system used to securely fasten or support cables and raceways. Perforated Cable trays provide for moderate ventilation with added cable support advantage.Power Kits offers Perforated Cable Trays in various standard dimensions including LENGTH (2500mm-3000mm), WIDTH (50mm–1200mm), HEIGHT (10mm-100mm), THICKNESS (1.2mm-3mm), which may be customized further as per customer design and requirements along with complete set of accessories for easy installation and maintenance.

Following the best industry standards, we use high quality raw materials and offer the following cable tray finishes-

- Mild Steel Perforated Cable tray (IS: 1079-1994)

- MS Hot Dip Galvanized Cable tray (IS:2629, IS:2633, IS:4759, BS:729, ASTM:A123)

- Pre-galvanized Cable tray

- Painted Cable tray (Red Oxide, Silver Painted or others)

- Powder Coated Cable tray

- Stainless Steel Perforated Cable tray (Grade 304 & 316)

- Self Finish Cable tray

- Matt finish Cable tray

- Mirror finish Cable tray

- Aluminium Perforated Cable tray (IS:737-1986)

- Self Finish Cable tray

- Anodized Finish Cable tray

- Pre-galvanized Sheet Perforated Cable tray (IS:513-1994)

To complement our customized Perforated Cable Tray offering, we also manufacture versatile support systems that have high tensile strength, durability and are easy to install. Our cable trays are best suited for applications in Electrical, Instrumentation and Mechanical Systems, for indoor as well as outdoor use and have found their way to various industries including Railways, Power plants, Thermal power projects, Industrial complexes and likes.

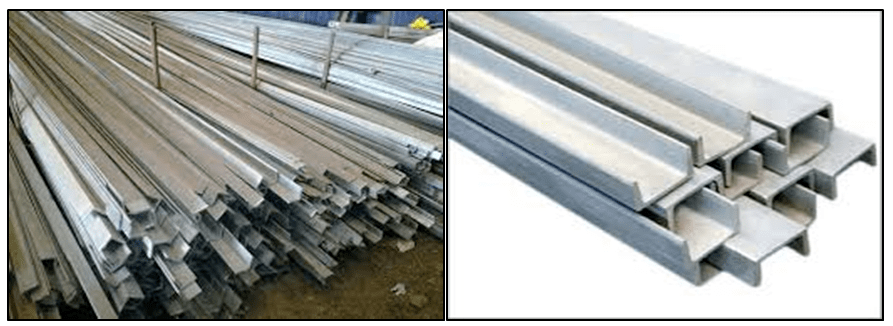

Ladder Type Cable Tray

Ladder type cable trays are used in various industries for distribution of power throughout the premises. These cable trays have uniform distance between them and consist of two longitudinal side rails or rungs, which are welded to the side rails or bolted in some cases. This type of cable tray provides maximum ventilation to heat producing cables.

Power Kits offers ladder type cable trays in various standard dimensions including, LENGTH (2500mm-3000mm), WIDTH (150mm–1200mm), CHANNEL HEIGHT (50mm-150mm), THICKNESS (1.6mm-3mm), RUNG WIDTH (30mm-50mm) and RUNG C to C (250mm-300mm). These may be customized further as per requirement and design specifications.

Customers may select the raw material and finish of the product depending on the use and specifications, including-

- Mild Steel (IS: 1079)

- MS Hot Dip Galvanized (IS:2629, IS:2633, IS:4759, BS:729, ASTM:A123)

- Pre-galvanized

- Enamel Painted

- Powder Coated

- Pre-galvanized Sheet (IS:513-1994)

Cable tray support systems are preferred over conduit wiring systems in terms of safety, dependability, space and cost. Ladder type cable trays are suitable for any sector and application from light to heavy duty requirements. They offer high resistance to corrosion, insulating properties, light weight and long life span.

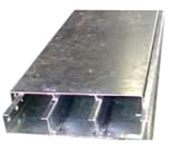

Raceways

We manufacture Cable Raceways to suit the needs of any commercial, residential or industrial use. We design and customize Floor Raceways, Ceiling Raceways and likes, of desired customer specifications and thickness. Customers can avail cable raceways in different finishes like-

- MS cable raceways,

- Hot- dip galvanized cable raceways

- Powder coated cable raceways

- Painted cable raceways, etc.

Cable Raceways are an affordable way to run networking and power cables throughout IT Companies, Commercial and Industrial establishments. These can be used in ducting wires and cables for various applications and conduit of cables and wires in multistory apartments, high-rise buildings, malls, mobile towers, power plants, industrial units etc.

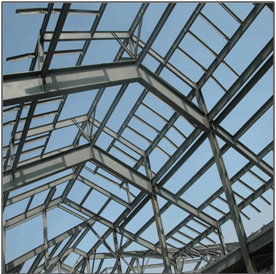

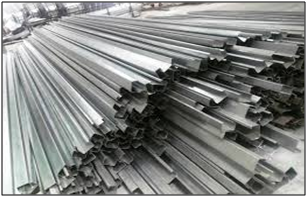

Structures

Steel structure fabrication process is systematic and requires utmost planning, precision and knowledge. The structure must be accuratelyfabricated before assembling it together. All component parts of the structure including the rivets, bolts, down to small amounts of welds, require professional expertise and skill, and at Power Kits, we offer just that.

Power Kits is well equipped with required tools, machinery and experienced professionals to create Hot-dip galvanized structures like beams, trusses, hollow sections, angles and plates, to name a few.

We manufacture unique structures varying in sizes, dimensions, and designs. Each structure is specifically designed and fabricated as per customer drawing and specifications. We employ various fastening methods to deliver different finishes to these structures including MS self-finish, MS hot-dip galvanized finish as well as Painted finish as per the requirement of the customer.

Solar Structures

Solar mounting structures are essential for the appropriate design and function of a solar photovoltaic system. They provide the structural support needed to sustain solar panels at the optimum tilt, and can even affect the overall temperature of the system. Based on the selection of the solar mounting structure, the cooling mechanism also varies. At Power Kits we manufacture and provide customized solutions, understanding the needs of our customers with different technical specifications.

Our GI steel solar structures are thick in frame and polished as per specifications providing a long working life. We also provide all the necessary accessories for hassle free installation and support. We manufacture structures like -

- Rooftop Mounting Structure

- Poll Mounting Structure

- Ground Mounted Structure, and others.

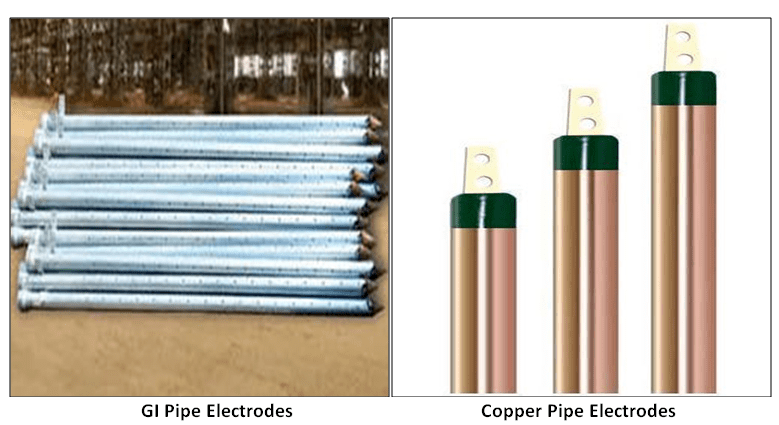

Earthing Material

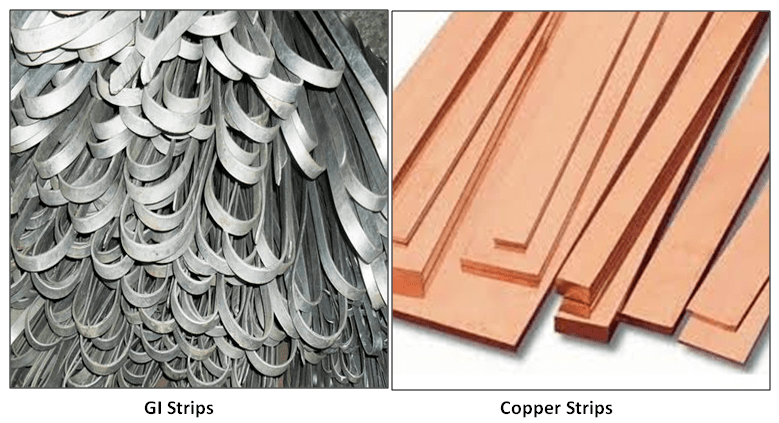

Power Kits offers a comprehensive range of high quality solutions that are widely used in earthing systems and play a vital role in all electrical systems. Available in different widths and thickness and manufactured in accordance with highest industry standards (IS:3043), by team of experienced individuals, our earthing material is known for its excellent conductivity, high load carrying capacity, durability and outstanding corrosion resistance. Our product portfolio includes-- GI Strips

- Copper Strips (Available in Standard sizes including- 25x3mm, 25x6 mm, 40x6 mm, 50x6mm, 50x8mm, 50x10mm, 65x10mm, 75x6mm, 75x10mm, 75x12mm, which can be customized as per requirements.)

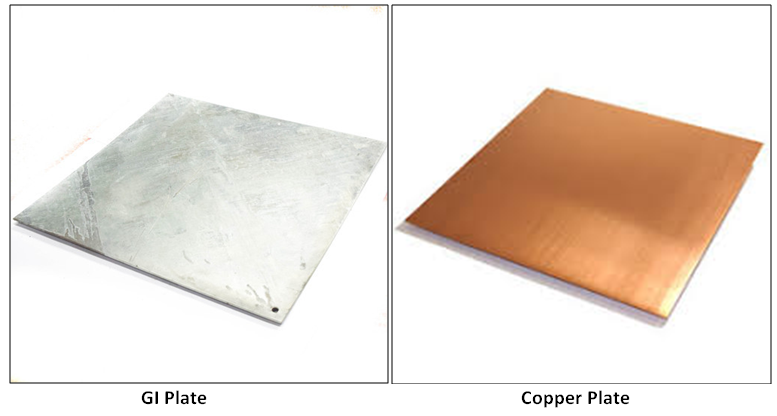

- GI Plates (IS: 3043)

- Copper Plates (Available in 600x600x3.15mm, 600x600x6.3 mm, 1200x1200x12mm, which can be customized as per requirements.)

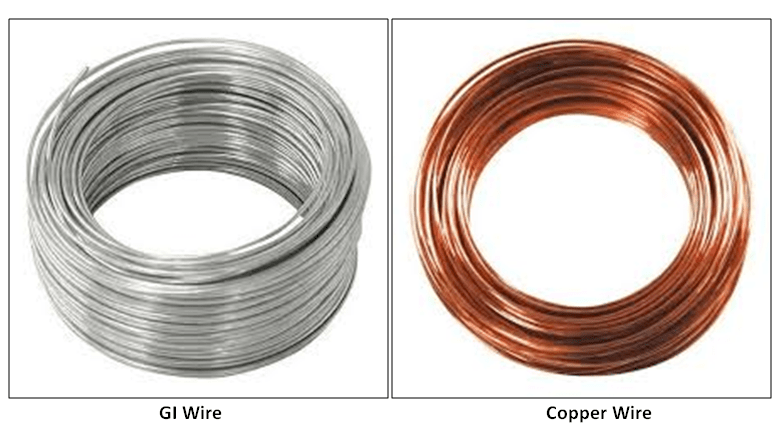

- GI Wire

- Copper Wire (Available in standard sizes as well as other non-standardized sizes as per customer specification and designs.)

- GI Electrodes

- Pre-galvanized GI pipe

- MS hot-dip galvanized pipe(IS:3043)

- CI pipe electrode

- Copper Electrodes (Available in standard sizes including dia. 40mm, 50mm, 65mm (EIL Specs), 80mm (PDIL specs) as well as other non-standardized sizes as per customer specification and designs.)

- Copper flexibles, and others. (Available in standard sizes as well as other non-standardized sizes as per customer specification and designs.)

As Earthing is one of the most essential part of any electrical layout, generally, larger is the building, more complex

are the earthing systems and thus more experience and expertise come into play. Keeping the main objective behind

laying of earthing in mind i.e., for providing alternative channel for the faulty electricity to flow through and ensure

safety, we have successfully manufacturered and installed our products for various reputed companies across India

over the years.

Steel Tubular Poles (Swaged Poles)

Swaged type steel tubular poles are designed and customized to meet the versatile demands of architects, engineers, planners and more for power distribution, illumination, signage and other diverse needs. We manufacture poles to suit the needs of the customer using sophisticated machinery, managed by an excellent team of experienced and qualified personnel.

Steel Tubular poles are manufactured conforming to design 410-SP-Mpa, IS:2713-1980 standard. The design, specifications and finish can be customized as per the customer.

Our steel tubular poles offer excellent durability and reliability. These poles come with strength and stability to withstand torsional stress, offering minimum wind resistance and perfect elasticity to take all kinds of shocks, cyclones, thrust line breakages, etc.

M.S. Hot Dip Galvanized / GI Pipe Poles

GI poles are appreciated for their longer organic life, simple installation and outstanding quality. The poles are fabricated and subjected to methods like twisting, programmed welding, framing, hot dip galvanization and powder coating. Backed by a proficient team of experts, we at Power Kits ensure the best quality in galvanized iron poles. The fabrication is done using high-quality steel, and the poles are tested and designed as per the present day industry norms. Our poles have found their application in various industries including refineries, thermal power plants, fertilizer plants, to name a few.

Hot Dip Galvanization acts as a protective shield for the poles and protects it from external factors and components. Absolutely corrosion free, our poles are extremely resistant to adverse weather conditions. The construction is robust and durable making installation process natural and hassle-free.

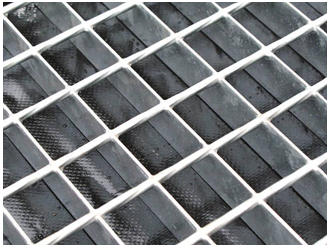

Gratings

Gratings are specifically outlined to offer long-lasting, worry-free, economical and safe solutions in areas where chemicals and different corrosive attack wood, metal and allied materials. These load-bearing, panel-shaped elements, offer numerous design options and leave room for aesthetic considerations and can be combined with other materials in an impressive number of ways.

At Power Kits, we manufacture Gratings in various sizes, as per drawing and specific requirements. Customers may choose the finish in black, painted in red-oxide, silver painted or hot-dip galvanized, depending on the use and required setting.

Gratings can be used outdoors in industrial premises, public and private buildings and in agricultural settings as well as for traditional indoor uses including the covers for ventilation shafts, heaters and air-conditioning system vents etc. as is simple, convenient to install and safe. We use high-end raw materials and multiple production processes to ensure superior product quality.

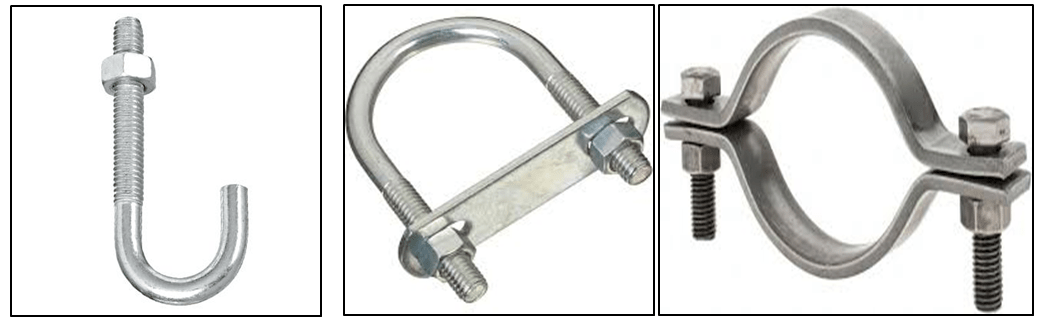

GI Hardware

We manufacture made-to-order as well as standardized GI hardware that is made with precision and accuracy. Our well-equipped manufacturing unit with our master technicians and testing facility, enable us to deliver high quality products. We offer various types of GI hardware including-

- Foundation Bolts

- J-Bolts

- U-Bolts

- Clamps

- Anchor Rods, and others.

Offering the flexibility to customize the design and size as per need and requirement, our products are known for their high corrosion resistance, quality finish, tensile strength and precise threading as per measurements.

Power Kits follows IS standards (IS:2629, IS:2633 and IS:4759, as applicable) for hot dip galvanizing process at our manufacturing unit. We understand the importance of high quality and also provide the facility for 3rd party inspection and test certificate on request.